DAY 14...... Engine theory.

Bits in red I need help with

Today started off well....100% correct answers for our weekly knowledge test with which I'll sum up:

Principle role of an Int. Comb. Engine: ''to take chemical energy, provide a place to heat it and turn the recipricating (linear) energy created into rotary motion which will eventually rotate the wheels''.

Piston and crankshaft indentification (easy)

Purpose of the HG: ''To provide a seal between the block and head so as not to allow combustion, oil or water to escape.

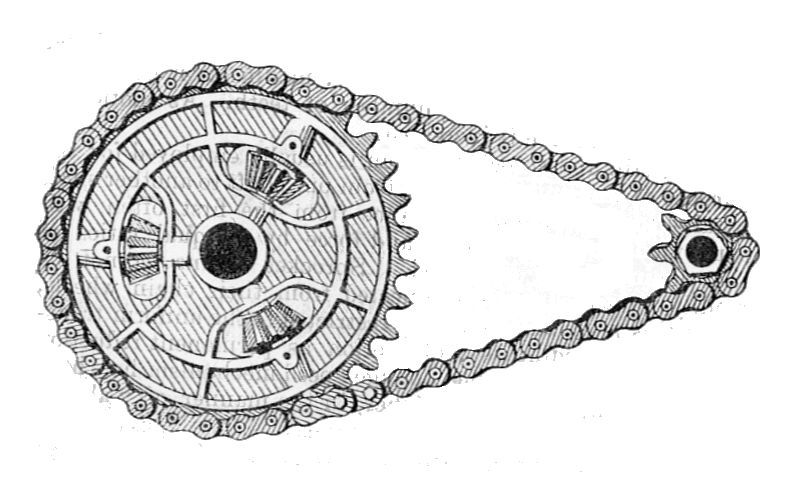

Crankshaft to camshaft rotation ratio: 2:1 (important note to self that even though the cam shaft will only have one turn to two of the crank, the cam sprocket will have twice as many teeth as the crank sprocket).... plus one full four stroke cycle equals 720o crank rotation, 3600 cam rotation.

Identification of a chain drive:

State the location of a mid engine.... rule of thumb: mid engine in front of rear axel, rear engine behind rear axel.

Indicate a rocker and camshaft on a Overhead Valve (pushrod engine).... camshaft at bottom near crank which pushes push rod up and that in turn pushes the rocker (located at the top) downwards to open the valve.

And some other stuff that was easy that I shan't bother to note

Anyhow.... I mentioned that it went well. which it did. then it got hard and confusing

although on reflection I think i get it

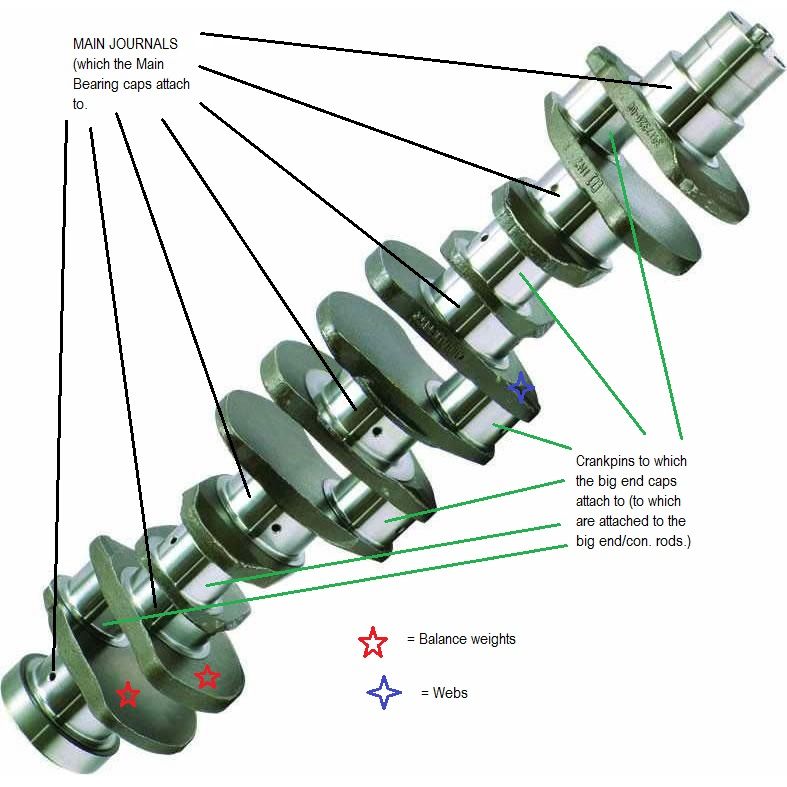

Ok firstly we labelled up the exact parts of a crankshaft and i labelled up this google image which shows the different parts:

one really interesting thing i didnt realise until today was that the balance weights have the holes in them for literally that reason...balancing... like you'd add weight to the light area of a wheel to balance it, the balance weight is drilled of metal to balance it

Ok, here's where it gets tricky....

How torque is produced in the engine....

now i qualified with the teacher that the only place in the engine where torque was produced was from the pistons. but having said that there are other areas that torque is used, obviously one we all know: the tightness of nuts and bolts using a torque wrench. however this discussion centred around engine torque....

ok, so torque is twisting force. to calculate torque it force X radius. SO

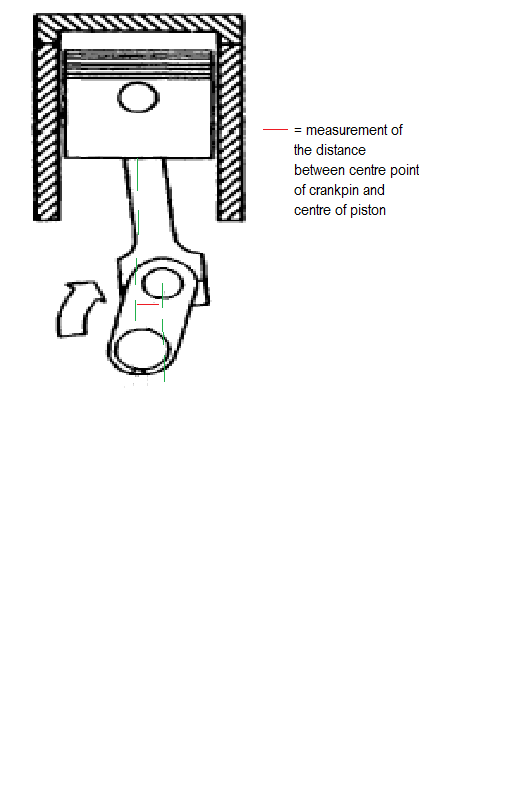

the spark occurs at the very end of the compression cycle, 10o before the piston is at TDC. Rapid burning occurs for 20o so when the piston reaches 10o PAST TDC it produces it's maximum force because there's maximum cylinder pressure and this then has the effect of shooting the piston down. NB, this pushing/shooting force could not happen at TDC because the radius would be 0

o and therefore no leverage which is what you need to produce torque.

To measure the radius is where it gets dfficult (for me anyway).... it's easy with a torque wrench because when it's used at 90o to what it's tightening the radius (or leverage) is simply the length of the torque wrench

HOWEVER below is how to work out the radius with regards to the crank and pistons (i've drawn this so sorry if it's a bit, errrrm, shite lol:

NEXT: VALVE SPRINGS

to sum up the cam operates the spring and allows it to shut. the spring keeps it closed and holds the valve shut until the next time the cam opens it.

Surging/Resonating: this is vibration created (at certain engine speeds) parellel to the valve guide.

is this linear (up and down) vibration or side to side vibration?

most common spring is the helical coil spring as they're easier to fit compared to hairpin springs due to them being smaller and fitting in the tight space available:

ways manufacturers deal with resonating is to make the spring more tightly wound... less room to vibrate.

and also two springs fitted in to one

really? why would this work? didnt understand the explanation really

Anyway that concludes today's theory. I'm not in again until Monday but I have been given some stuff to research which I'll add to the group for discussion

Author

Topic: Mechanic School Blog (Read 94632 times)

Author

Topic: Mechanic School Blog (Read 94632 times)