So watched the F1 for a bit keeping an eye on the weather and it stopped raining for good about 2. So gave the welder a blast.

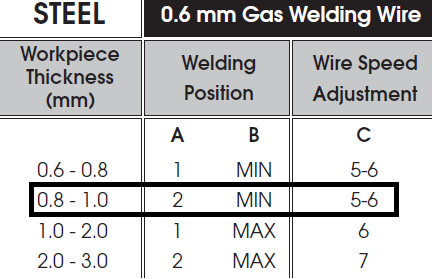

I measured the thickness of the metal to be welded. just under 1mm so set up the welder as per the below settings:

Gas regulator set to 4 as recommended.

First weld, burned straight through

I was keeping an ear out for the sound and it was ''cracking'' as opposed to a continuous buzz. So I turned the wire speed down and that seemed better.

Please don't mock

these are my first attempts at running beads...as you can see there are some burn throughs. but after playing around with the settings there were a few that I did that I thought ''hmmm, not bad'' but in honesty most are terrible.

Second piece of metal. This frustrated me cos I just couldn't seem to get the setting right. it was spattering, burning through and cracking.

Then finally as I had about 30 mins of light left I decided to try and weld two pieces together.... this was even worse. my first weld went brown

I had a think and I presume these are oxidised cos the gas has run out? but either way absolute shit

to be fair I tried on loads of different settings and never could get it quite right apart from a couple of times.

then I thought.... I was outside (although in an alcove in the garden to try and get out of any wind)

but im a persistent bear and will keep going/ next attempt...Thursday

Author

Topic: Welding Blog (Read 22985 times)

Author

Topic: Welding Blog (Read 22985 times)