Driver's wishThe first map of interest is the Driver's wish map. This map is for requested IQ by the driver based on RPM and throttle position.

It is located at 0x7DA0. Let's take this map as an example on how to read axes and dimensions of the map.

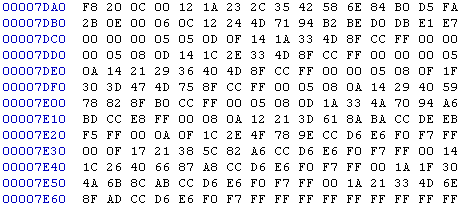

Here it is in hex form:

F8 20 is an axis identifier. 20 in this case is RPM. After the axis identifier there is the axis length, which is 0C or 12 in decimal.

After the length are the actual axis values themselves. 12 of them, as the length indicates.

Now comes the next axis identifier - FA 2B. 2B is throttle position, and it's length is 0E or 14.

So what can we conclude from this? We have a map of RPM x Throttle position, with the dimensions of 12 x 14. The only such map in this ECU is the Driver's wish, and it's output is IQ.

Of course you don't always know the axis identifiers. While RPM is usually 0x20 in these older ECU's, throttle position can vary, but you can also tell the maps apart by their shape.

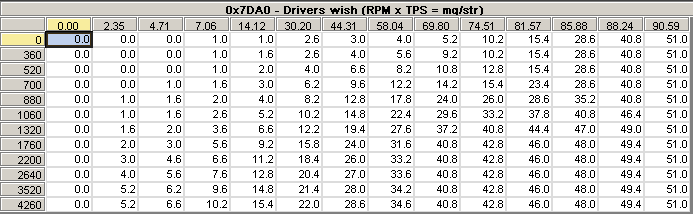

Let's take a look at the map with conversions applied. For RPM this is X*20, for TPS it is X/2.55 and for IQ we have X*0.2 in this ECU.

Here is the map itself in TunerPro:

And in 3D:

Tuning this map allows us to adjust how the throttle reacts. When tuning for performance, the important part is to make sure that enough IQ is requested.

We can see that the last column (>90% throttle opening) always requests 51mg/str. Since 51mg/str is the maximum in this ECU (255*0.2=51), this map does not need to be modified, unless you want to alter throttle pedal behaviour for some reason.

Smoke limiterThe smoke limiter map limits injected IQ based on mass air flow read from the MAF. If we did not have this map, the engine would be flooded every time the driver gave the car a lot of throttle, because there would not be enough air in the engine to combust the fuel.

Why is it called smoke limiter? Because diesel starts to smoke quite a bit when it is running rich, so this map limits smoke among other things.

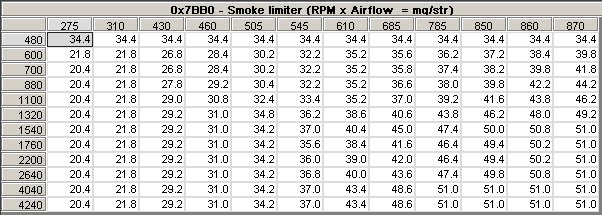

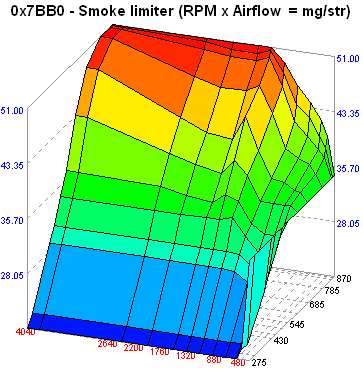

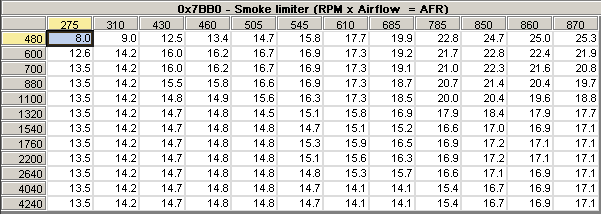

The map is located at 0x7BB0, it is a 12 x 12 map with the inputs being RPM and Airflow and the output being IQ.

Airflow is also mg/stroke, and the multiplier is X*5

Pictures:

If you think for a moment, you will realize, that this map in reality is an AFR rich limiter.

The Y axis in the map is air in mg/stroke and the output values are mg/stroke as well.

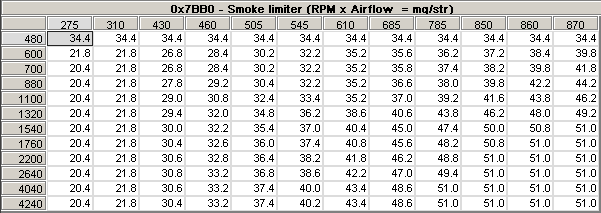

Instead of doing the calculation in your head all the time, let's just change the way we are presented with the data:

This is a lot easier to work with, and makes much more sense.

To tune this map, we need to understand how the car drives. The torque converter lockup is around 1500 rpm on this transmission. The car is very heavy (close to 1900 kg) and the turbo is not of a VNT technology, so there is turbo lag until 1900-2000 RPM.

The biggest problem is response when starting to move from standstill. We can see that the original calibrator saw this problem, and allowed for richer AFR's at the 1540 RPM point, however, at 1760 RPM this is backed off again.

Here is an illustration with the area in question highlighted:

Since the car does not really smoke (only a very light puff) at 1500 RPM, from a performance standpoint there is no real point in backing off max rich AFR at 1760 RPM.

Also, it is possible to add a little more fuel at 1540 RPM as well, to make the car a bit faster off the line.

We can also make sure that the top end (airflow > 850 mg/stroke) is not limited by the map and the ECU can always inject enough. The maximum once again is 51 mg/stroke (255).

The final tuned map looks like this:

Or in AFR mode:

Torque limiter

Torque limiterIn this binary there are two of these maps, and they are identical. The map is used for component protection through engine torque limitation.

The maps are located at 0x75E0 and 0x7610, and have 20 values, based on RPM.

When tuning limiters it is very important to understand what exactly you are doing and why.

With the stock automatic gearbox, this map can't be tuned at all. The stock gearboxes barely handle the stock torque (and tend to fall apart), never mind increased torque. But my car's gearbox is not stock, and it is specified to handle 350nm, which this engine will not reach without hardware mods.

Also take note of the end of the map. This map is basically a rev limiter as well. On the stock map the rev limiter is very soft. We don't need it to be as soft, we just need it to be there.

The Omega is rated conservatively as 130 PS, while BMW's with the same engine have 145 PS. The only noticeable difference in the calibration is the torque limiter.

If I remember correctly, BMW's go up to 47 mg/stroke, while this car is limited to 43.

Assuming the gearbox has been upgraded, the map can be set to 51mg/stroke throughout for a nice power increase. This will net about 20 extra horsepower.

Here is a picture overlaying the original limiter and the new limiter.

Because there are two identical maps, both have to be modified.

Author

Topic: Inside the 2.5TD ECU (Read 27766 times)

Author

Topic: Inside the 2.5TD ECU (Read 27766 times)