Right then, that's induction taken care of. Now onto cam covers and spark plugs.

Not the easiest job in the world as on some things it isn't too obvious what to do. So allow me to share a few tips that I picked up off others and a couple that I figured out for myself.

Tools for the job include female Torx socket E10, Vauxhall cam cover gasket set, and Vauxhall cam-cover gasket sealant. Whilst you are in the you may as well change the spark plugs, so add to that list 6 GM spark plugs, a small spark plug socket (14mm?), copperslip, a straightedge to check your cam covers aren't warped, (I used a mental ruler), and most importantly a torque wrench to torque up your spark plugs and cam cover / dis-pac bolts. Due to the low values that these get torqued up to, and the lack of room on the passenger side, I think that only a 3/8th torque wrench will fit.

Spark plugs need to be torqued up to 25NM (18 lb/ft), and the cam cover / dis-pac bolts to 8NM (6 lb/ft).

Once the plenumn and intake trumpet are removed, access at least to the drivers side is pretty good.

For me at least, how to remove the dis-pac wasn't obvious, but thank to a couple of helpfull chaps on here,I soon got pointed in the right direction

Around the edge of the dis-pac, (the long dark grey box that sits atop each cam cover), is a rubber lip or seal. Once all the bolts are removed, gently prise away this rubber seal and gently prise out your dis-pac. Chances are that you will break the plastic edging of the dis-pac at a couple of points, but this should really cause any problems so long as it isn't too badly damaged.

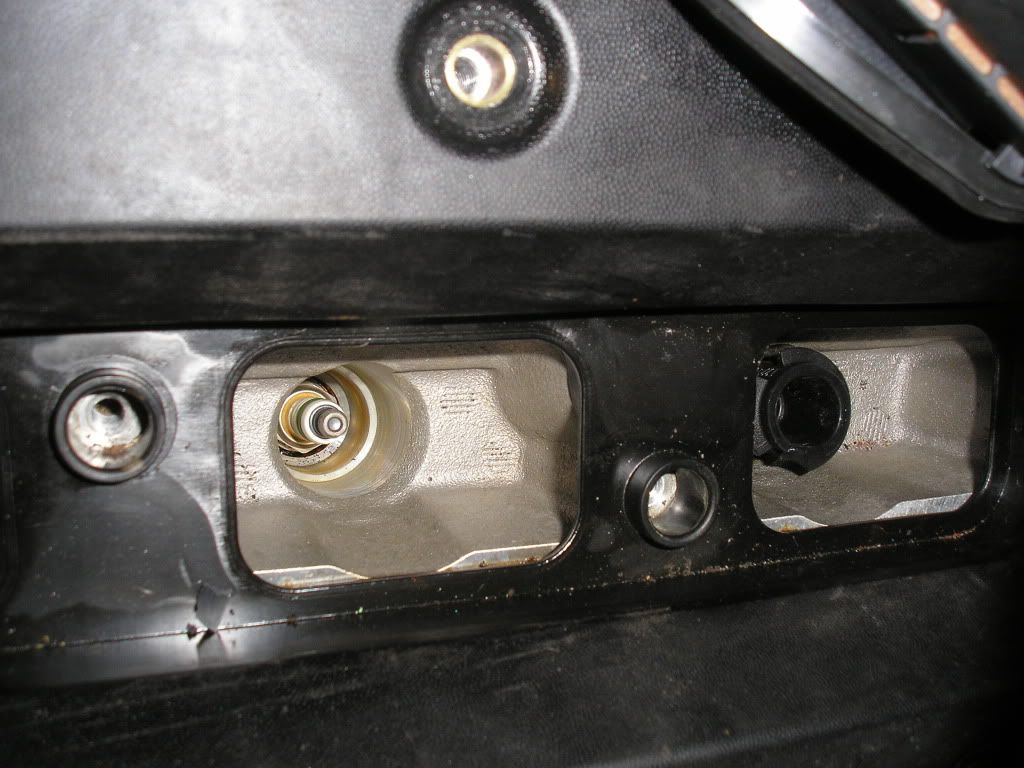

If your lucky then the dis-pac will just pop right out complete with all it's shrouds. If your not lucky, some of the spark plug shrouds may stay stuck to the plugs, like in the picture below;

Then they are quite tricky to remove. After getting advice on here, I figured the best way to get a stuck spark plug shroud out was to put plenty of WD-40 / TT / Plus-Gas down there and try and break the seal and pop it out with a couple of screwdrivers. This does take time, is annoying, and will damage the sparkplug shroud. If the car is your only motor, I'd suggest trying to pick up a few spare shrouds prior to starting the job. These aren't available at Vauxhall, (unless you want to buy the dis-pac as well), nor did I have any luck on eBay, but if someone is breaking a car, or there is a scrapyard nearby then you may be in luck. Sods law will dictate that if you don't have any spares, you'll end up needing them. If you do have them, then you likely won't need them

Once the dis-pac is removed it's time for changing the plugs. As I understand it Vauxhall suggest putting the plugs in dry, (not using any copperslip). On my plugs they were rather difficult to remove, and I fear that on a couple of them, if they had been done up much tighter then getting them out would have damaged the threads on the cylinder head.

old plugs out, (1/3/5 top and 2/4/6 bottom);

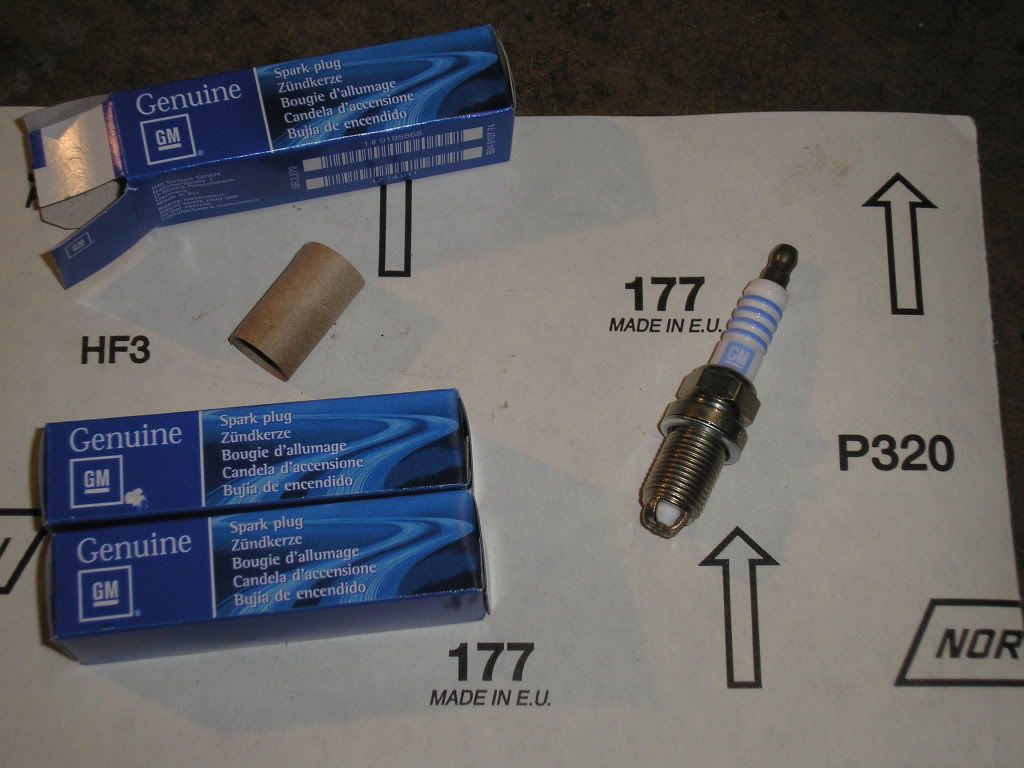

Although the old ones didn't look 'too' bad, I replaced them all anyway;

Upon doing so I added some copperslip to the threads in order for the spark plugs to come out a little easier next time. What I may also do is add a little copperslip to the tops of each spark plug, which should reduce the chances of the shrouds getting baked onto the plugs.

Putting the new plugs back in, I have heard of folk using an old piece of hosepipe in order to not get the plug cross-threaded. I didn't bother. Instead I just used a long extension for the ratchet, (but without using the ratchet). Doing it this way it was easy to feel any significant resistance when screwing the new plug back in, (at which point I un-wound and started again), doing them up finger tight, before finishing off with the torque wrench (25 NM).

The GM plugs are pre-gapped, but even so I would reccomend just giving them a visual check, just to make sure that the electrodes aren't damaged.

Now onto the cam-cover gaskets. Drivers side first and loads of room to work on this one.

Lift the dis-pac up and out of the way, placing in the recess where the intake trumpet would usually be. With the 8 cam-cover bolts removed you can now remove the cam-cover.

This may be stuck slightly, so I tapped mine gently with a rubber mallet, whilst using an old screwdriver to again gently tease the cam-cover away from the cylinder head.

With the cam-cover removed, carefully remove any old tracers of sealent and gasket from the face of the cylinder head using carb cleaner, an old cloth and a scraper, being very carefull not to drop any old sealant / gasket material into the camshaft workings or oilways. Once the face of the cylinder head is cleaned up, move onto the cam-cover itself.

Prise out the old gasket and the eight 'O' rings that sit in the recess of the bolt holes. I used this tool from Machine Mart;

http://www.machinemart.co.uk/shop/product/details/cht161-4-piece-mini-pick-hook-setThen once all the old gasket, sealant and 'O' rings have been removed, use the straight edge to check that the cam cover isn't warped. If all is ok move onto fitting the new gaskets and 'O' rings.

Here is why it is important to get the face of the cylinder head cleaned up first. The sealant that you will be using only has a short timespan before it goes 'off'. if you haven't cleaned the heads up first, then by the time that you actually have done so, the sealant will have cured already, reducing it's ability to make a proper seal.

Author

Topic: Getting her back to tip-top. (Read 14078 times)

Author

Topic: Getting her back to tip-top. (Read 14078 times)