Ok boys, I'm home, relaxed, I have my tool kit, a lamp light and I have a multi-meter borrowed from the lovely technician from school

I'm praying someone can answer my Q's tonight as I only have this multi-meter for tonight (don't want to push my luck too much

)

These were the results from a TechII session with TB (thanks mate):

When he turned up, O2 BLMs:

Integrators, around 100 (low)

Idle (B1 - 190, B2 - 160) (high)

Partial Load, around 130 (good)

Air/fuel ratio (Rich/Lean) seemed sluggish at idle, flipped at about 1Hz at 2000rpm, lazy lamdas, both banks.

Reset BLMs, took for drive, all around the 130 mark, except at idle, when integrators crept to 150ish, with Air/Fuel showing lean until then, then flipped at 0.33 - 1Hz

Seemed slightly down on power to me, although Webby said otherwise. MID readings for instantaneous consumption seemed quite low - I'd expect mid to high 30s average when cruising 50-60mph, reality was mid/high 20s. MID has correct 035 config, and readings seem to match Webby's experience of it using more fuel recently. This leads me to suspect that the engine is really using that amount of fuel, rather than leaks (which I couldn't detect, or smell).

After test run, brakes still cold. EGR can get to about 55% before the thing really splutters. Injector cut-off exactly as expected.

MAF, at idle, with A/C off, 9kg/hr.Last Sunday I got the EGR cleaned out (thanks Martin) and I did an oil change and she runs lovely and seems to want to go!

but still getting the high consupmtion.

People who know me know I have to have my house in order otherwise I get all confused hence the massive thread (so apologies fo that) but this is what I'm going to do. All you have to do is tell me if I'm wrong or right in my approach...

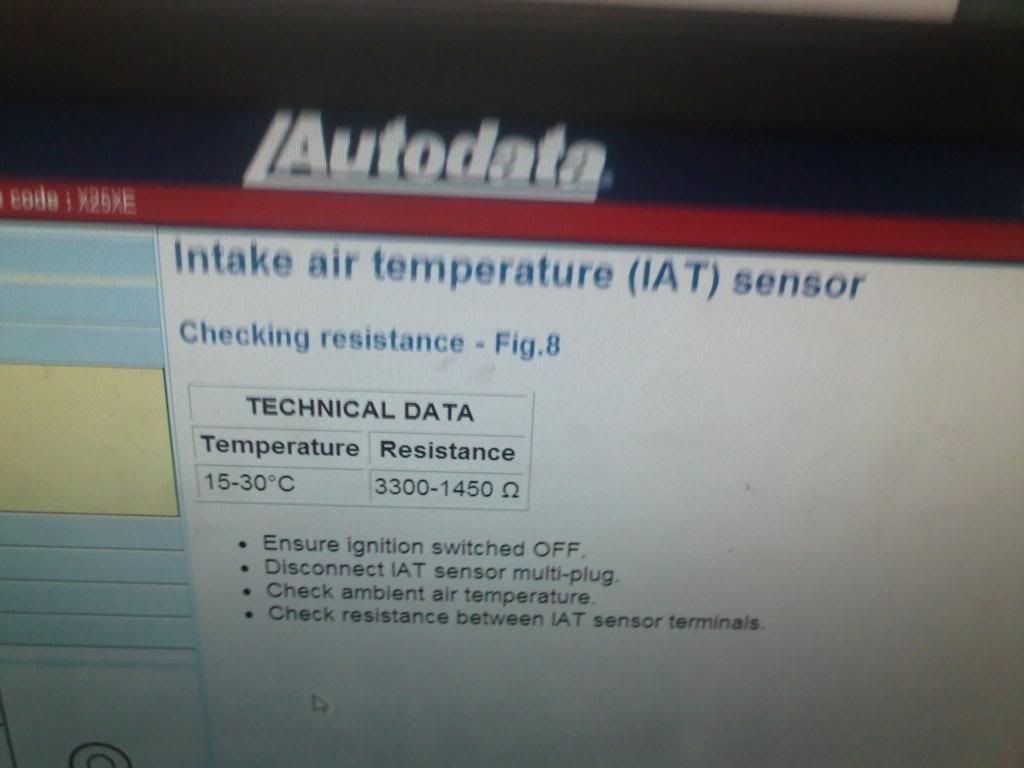

oh and questions in red  INTAKE AIR TEMP. (IAT) SENSOR

INTAKE AIR TEMP. (IAT) SENSORI've actually done this already tonight

As per Autodata it says to switch ignition off, disconnect the sensor, check ambient temp. and check resistance between the sensor terminals (two of them).

Autodata says ambient temp. should be 15-30

oC. And the resistance readings as per below.

I had just ran the car for about twenty minutes so things were ''toasty'' under there so I presume that's why I'm getting a high resistance reading of 2040 ohmes (2.04 on the 20k scale).  MAS AIRFLOW (MAF) SENSOR

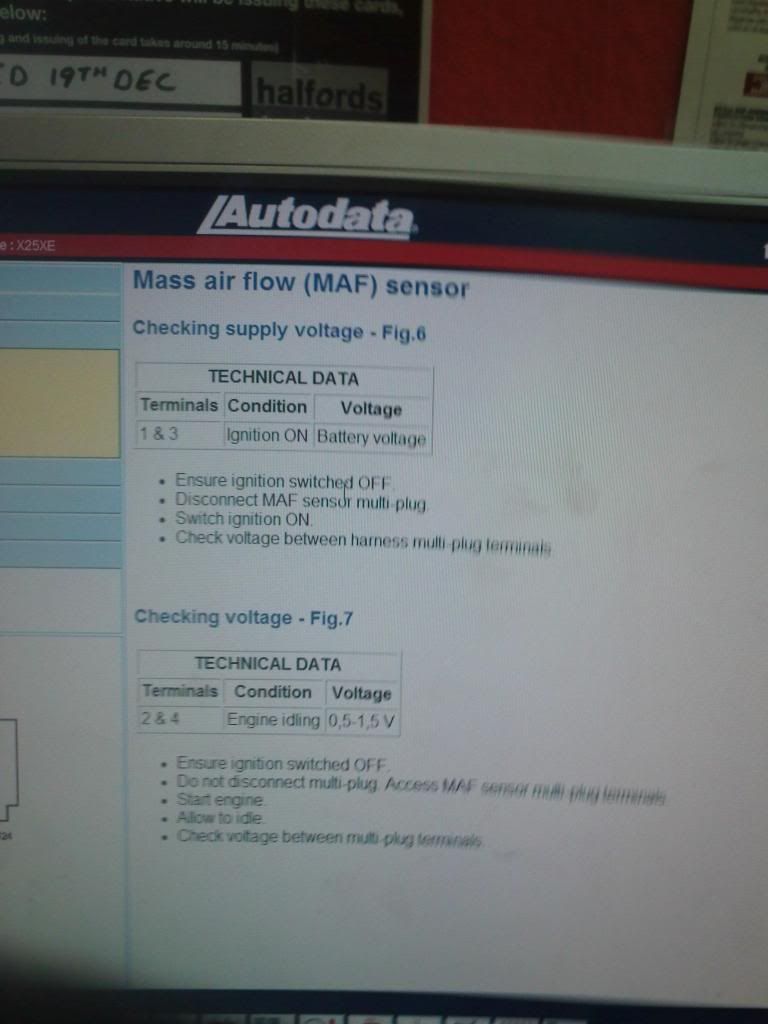

MAS AIRFLOW (MAF) SENSORI haven't done this one yet as it's just started raining

(am going out there again irrespective of the rain as I'm determined to clear this up). Anyway the procedure I'm going to follow is this...

I have two options for voltage... AC or DC. Which one should I use to check the voltage??? THROTTLE POSITION SENSOR (TPS)

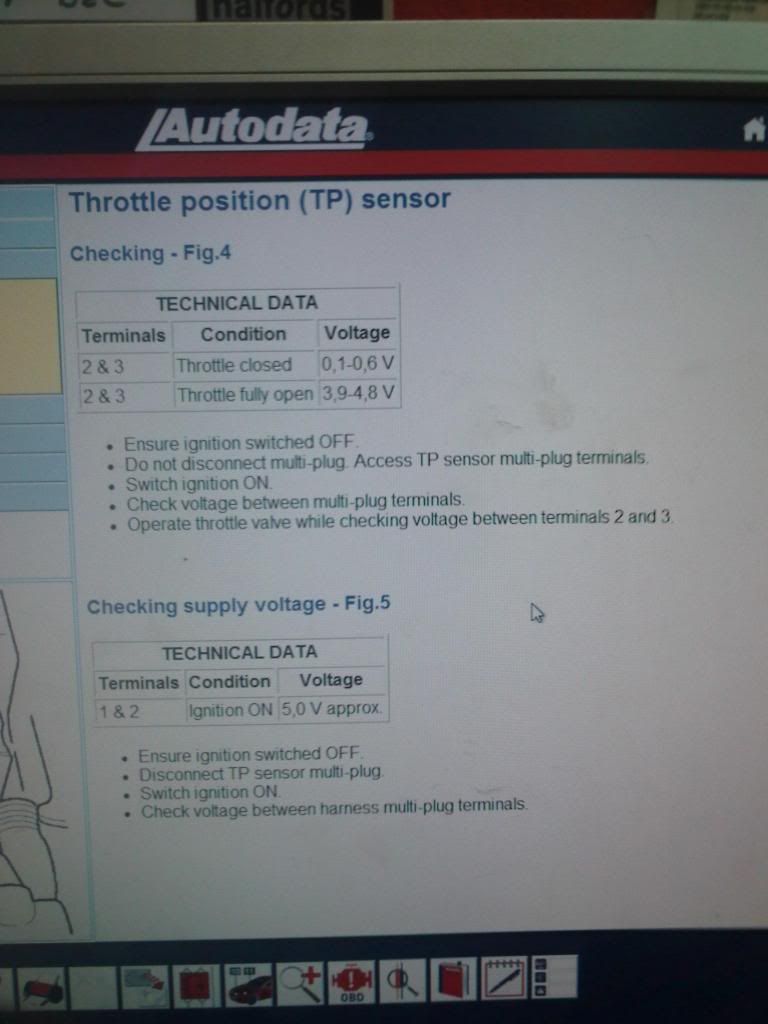

THROTTLE POSITION SENSOR (TPS)Again, I haven't done this one because of the rain but again procedure I'll follow...

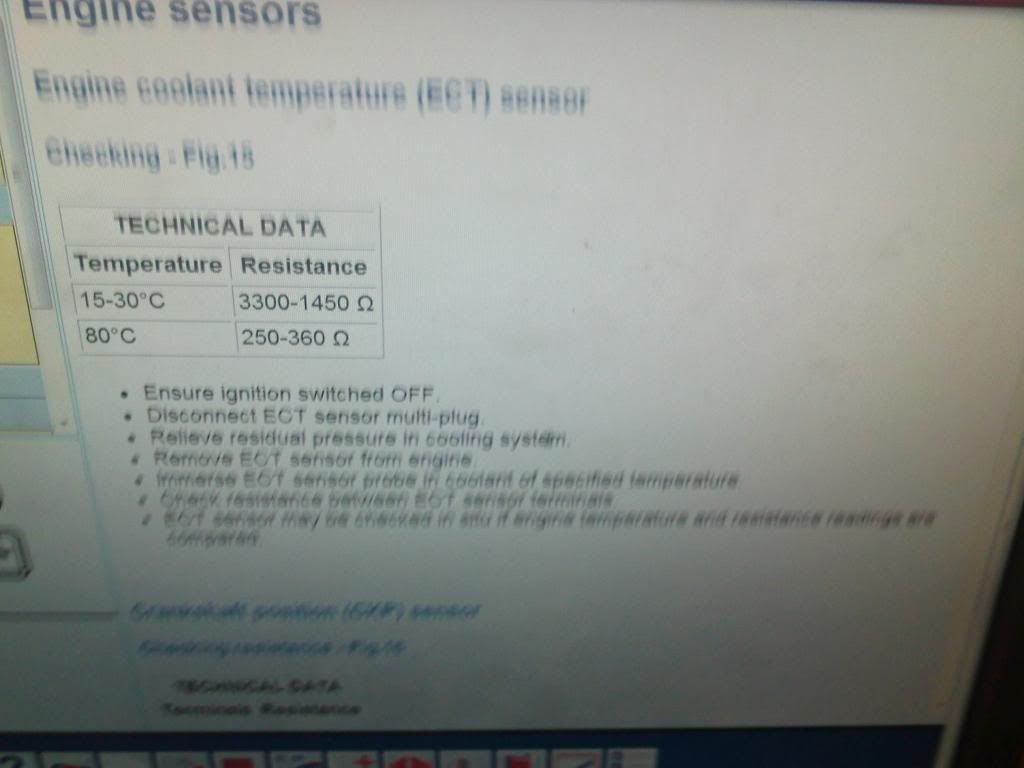

When it says access TP sensor multi-plug terminals... but don't disconnect the multi-plug... wellhow the hell am I supposed to check it??? lol. And both of these checks on the image (Fig. 4 & Fig. 5) I'm supposed to check the actualsensor itself and not it's plug going in??? COOLANT TEMP. SENSOR (CTS)

COOLANT TEMP. SENSOR (CTS)Obviously, this isn't one for tonight but I want to get this bad boy done at the weekend. But here's the procedure I'm going to follow:

CHECKING BATTERY VOLTAGE

CHECKING BATTERY VOLTAGEI don't think this is going to affect fuel consumption

(or could it?

but I am aware it can affect performance and as I have the meter I may as well check it...

should be 12.5, not drop below 10 on start up and go to around 14.5 when running, right???EXHAUST LEAKSAs per Cem's posts (thanks for them mate) I am going to get the car up on the ramps at school and get someone to give it the beans while I'm underneath looking for smoke or any sign of exhaust leaks between the exhaust manifold and the O2 sensors.

If all of the above work out fine then I'm thinking I need to look at the commpression and do a leak down test. If that's ok then I'd have to reasonably conclude it's the injectors that are bad (leaking perhaps?)Lot of info there but if someone could confirm all of the above I'll love you forever

(not that I don't anyway you big set of girls

Author

Topic: Mechanic School Blog (Read 96006 times)

Author

Topic: Mechanic School Blog (Read 96006 times)