This week I've been mostly doing....

BRAKES, TYRES & WHEEL BALANCING.

Brakes first of all. Well we've only done disc brakes and drums next week

but disc brakes are stupidly easy.

We had to remove the pads and discs, measure them (including run out on the discs) and compare to spec and produce a report as to whether we would replace or continue to use (serviceable).

I've done brakes on 4 cars today and this was pretty much the same set up for all:

remove caliper (tie up out of the way)

remove pads

remove mounting bracket

remove disc holding bolts (if the person before remembered to put them back

)

remove disc

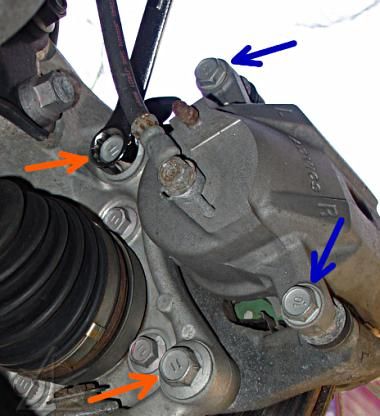

here's a pic of what the caliper bolts (blue arrows) and the mounting bracket bolts (orange)look like in situ.

now, what I do at this point is give the whole area a good clean with brake clean. wipe everything clean. you probanly don't need to every time but just for good measure I take emery cloth and lightly file the mounting bracket where the pads sit just to get the shit off.

I then take out my slide pins (ive noticed that most calipers one slide pin is in the mounting bracket and one is fioxed and part of the caliper). either way, lube them up with silicone paste...

now I never insist on anything and i'm always more than happy to be corrected but I wont on this!!

YOU MUST USE SILICONE PASTE ON THE SLIDE PINS. END OF!

Anyway, we weren't putting new pads in so there was no need to push the piston back. however if you were putting new pads in I pinch off the brake hose using these vice grips with bits of fuel line to protect hose...

...I then attach a bleed kit with tubing with a one way valve (to stop air getting in), push piston back and do up your bleed screw, unlock vice grips. DONE

So I then put a bit of copper grease where the disc will make contact with the hub.

I then put disc back, reattach mounting bracket, lube pads with copper anti seize paste where the pad touches the mount, reattach caliper, wheel back on. Pump pedal (just for good measure even though I didn't push piston back). DONE

As for measuring, well use a micrometer. pretty self explanatory. and to do the run out use a DTI whilst spinning the disc to get the run out reading.

not sure why I took a pic of this but here it is

also I thought this was pretty cool showing the brake system without the body...

TYRES & WHEEL BALANCING

I've only done this once so I don't feel confident at doing a guide

we're doing more next week so ill reveal all then but heres the equipment

this is called breaking the bead... I think ...

getting the tyre off the rim... now I don't know if this rim is fubard following the useless kids trying to do this

but looks nackered

this is actually quite tricky cos when you take the tyre off you have to get the lip on one side... and when you put it back it has to go on opposite.

and heres the balancing machine, really easy to use. tyre on, run it, it tells you what weight ands where to add. bash on the right weight. done

here's a vid of it being done by a pro though

http://www.youtube.com/watch?v=8hOZXIr1ujE

http://www.youtube.com/watch?v=8hOZXIr1ujE

Author

Topic: Mechanic School Blog (Read 95967 times)

Author

Topic: Mechanic School Blog (Read 95967 times)