[size=14]CCR2006 / CCRT2008 / NCDC2013 / NCDC2015 CD Autochanger failure[/size][/b]

The issuesAs these units start to age and with the use of CD-R media (for which they were never intended) the 4 disc autochanger laser starts to fail (generally giving focus errors) or due to a faulty disc caddy the internal changer mechanism becomes distorted and unuseable.

Why can Phillips / Siemens / repair centres not fix it?Unfortunately the laser units on these devices are no longer available and prove to be virtually impossible to purchase, this situation has arisen as Phillips no longer have their In Car Entertainment arm having sold it to Siemens who then dropped the Phillips products for their own.

The OOF solutionThe affected units can be repaired relatively easily and cheaply, basically the units affected are developed from earlier single DIN size units and as such are basically a single DIN head unit attached to a single DIN cd changer (that was originally marketed as a Phillips or Siemens CDC3) and a double DIN facia attached to the front.

In order to repair your unit you will need to obtain either a CDC3 or another headunit with a working autochanger element. Donít worry about the headunit or the facia being damaged or the wrong colour as they are not required.

But what about the security code / NCDx pairing?Fear not! The element that the coding / pairing requires will be swapped so you will not have to decode or de-pair/pair the units to effect the repair and in the case of the CCR2006, you will simply have to re-enter your code when you return the head unit to the car.

The How To!OK, so youíve obtained a replacement autochanger, next you need to locate these tools:-

Double DIN removal keys (not cheap Ebay ones!)

8mm socket and handle / mini-ratchet

T10, T9 Torx bits and handle

Small flat bladed screwdriver

A spring hook or small long needle nose pliers

Itís also useful to have a bowl to put all of the parts you remove into and ideally to either work on an antistatic mat or at least ground yourself before attempting this repair procedure.

NB. The photoís show the changer with the disc caddy in place, obviously you will want to eject the caddy when the unit is still in the car!

1) Remove your headunit from the car with your Ďqualityí double DIN removal keys, you will need to move the auto transmission selector to 1 to make enough room to extract the unit. To do this I suggest you pull up the selector surround, depress the catch at the top left of the selector mechanism then the selector can be moved without having to turn the ignition onÖ. Just make sure you have the handbrake engaged!

2) Now you have your headunit ready to disassemble, firstly remove from the rear the two 8mm nuts and then the joining plate.

3) Using a T10 torx remove the black Torx screw from either side at the front edge and the tin plate Ė mark which side is which!

4) Using a T9 torx remove the two facia plate retaining screws from either side at the front edge.

5)

Note: If purely swapping CD section, step 5 can normally be skipped.Place the unit upside down and using the flat screwdriver gently lift the two plastic facia retaining clips and the two further plastic clips on either side while gently removing the facia.

6) Using a T9 torx remove the two torx screws on either side,the CD autochanger should now be separate.

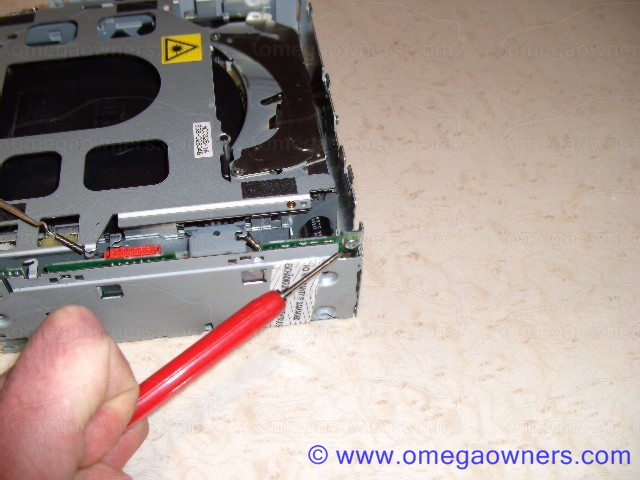

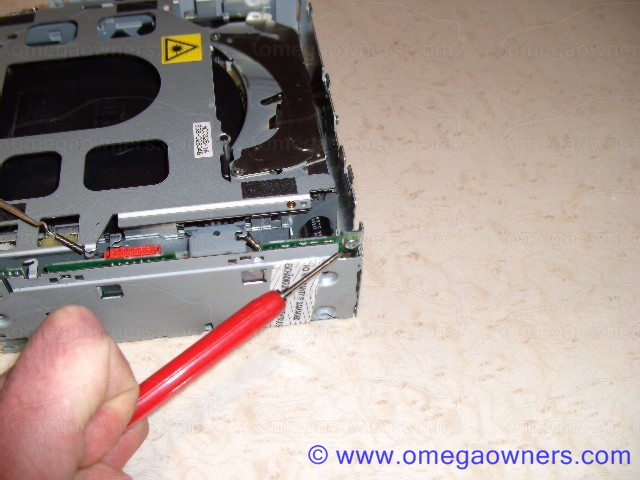

7) Very carefully remove the red ribbon connector plug from itís socket on the autochanger

Using a T9 torx remove the two T9 torx screws from the rear of the autochanger that secure the lid then gently slice through the warranty sticker on the right hand side (Iím assuming that a) you have no warranty and b) if you are doing this you arenít bothered about a warranty anyway!), you can now remove the lid.

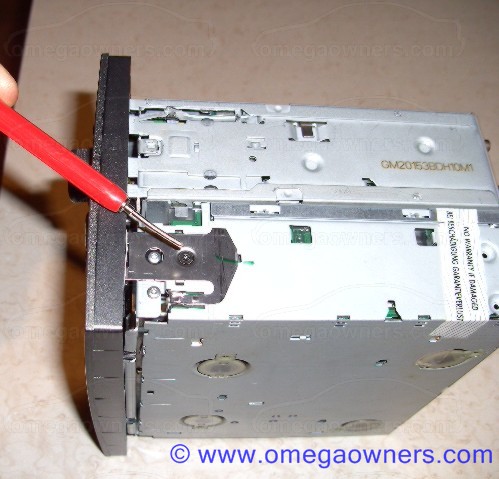

9) Using the spring hook or the small needle nose pliers unhook and remove the spring that hooks from the right hand edge of the autochanger mechanism to the chassis (this is the spring that goes over the top of the upright printed circuit board.

10) Using a T9 torx remove the T9 torx screw securing the printed circuit board on the rear right hand edge and then gently manipulate the board out of the unit (itís plugged into the main lower board), NB. The board is held in place by two metal clips, when refitting the board make sure that the board sits in the clips correctly.

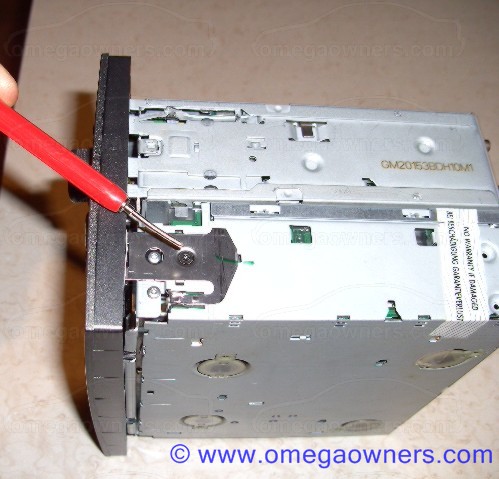

11) You now have to get your replacement unit to the same point, if you have managed to obtain the single CDC3 unit used in other GM models (Astra / Vectra etc) then you obviously have slightly less dismantling to do!)

Using a T9 torx remove the two T9 torx screws from the rear of the autochanger that secure the lid then gently slice through the warranty sticker on the right hand side (Iím assuming that a) you have no warranty and b) if you are doing this you arenít bothered about a warranty anyway!), you can now remove the lid.

Using a T9 torx remove the two T9 torx screws from the rear of the autochanger that secure the lid then gently slice through the warranty sticker on the right hand side (Iím assuming that a) you have no warranty and b) if you are doing this you arenít bothered about a warranty anyway!), you can now remove the lid.