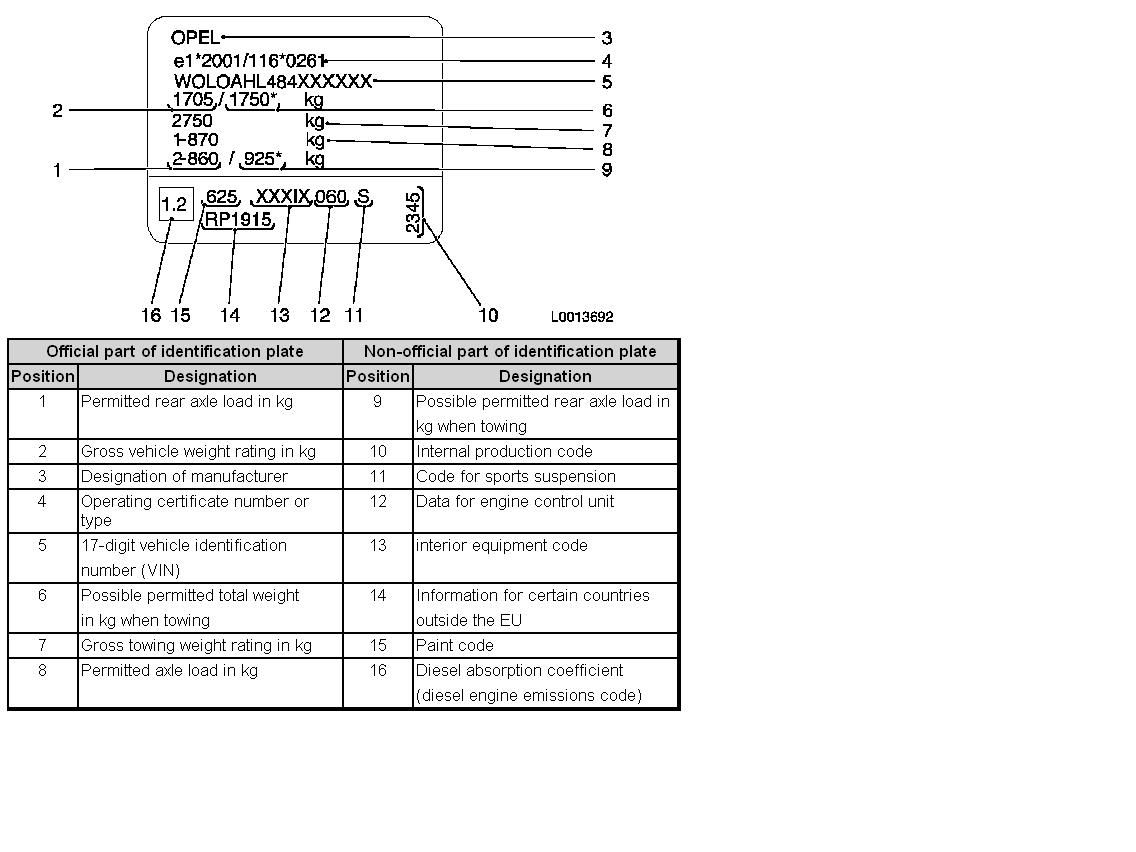

Note: The Omega cabin fuses are located below the steering wheel and are accessed by opening the drop down cover.

94-95 Cars 1--30A Window operation

2--15A Brake lamps, hazard warning flashers

3--30A Windscreen wipers, windscreen washer system

4--10A CD Changer

5--30A Electrically adjustable front seats

6--20A Radio

7--30A Electrically operated windows

8--10A Daylight running lamps (Scandinavia)

9--10A Automatic transmission (for the infirm)

10-

11-10A Heated exterior mirrors

12-20A Courtesy light, tunk lamp, hazard warning flashers, information display, radio

13-10A Electrically adjustable exterior mirrors

14-20A Power steering, cigarette lighter, heated front seats, electrically operated rear window blind

15-15A Reverse lamps, cigarette lighter, glove compartment lamp,automatic transmission, automatic level control system, cruise control, ventilation for rear door windows, position memory for seat and mirror adjustment

16-20A Fog lamps

17-20A Horn

18-20A Fuel pump (useful to remove then run engine to de-pressurise fuel system when changing fuel filter etc!)

19-10A ABS, TC

20-20A Heated rear seats, electrically operated rear window blind, central locking system

21-10A Main beam (left)

22-10A Dipped beam (left) headlamp range adjustment

23-10A Parking and tail lamps

24-20A

25-20A Sunroof

26-10A Number plate lamp, information display, headlamp washer system

27-20A Automatic level control system

28-10A Fog tail lamp

29-20A Terminal 30. constant current for caravan/trailer 30-10A Parking and tail lamps (right)

31-10A Dipped beam (right), headlamp range adjustment

32-10A Main beam (right), control indicators

33-30A Heater fan, air-conditioning system

34-40A Heated rear window

96-97 cars1--30A Window operation

2--15A Brake lamps, hazard warning flashers

3--30A Windscreen wipers, windscreen washer system

4--10A CD Changer

5--30A Electrically adjustable front seats

6--10A Radio

7--30A Electrically operated windows

8--10A Daylight running lamps (Scandinavia)

9--10A Automatic transmission (for the infirm)

10-

11-10A Heated exterior mirrors

12-20A Courtesy light, tunk lamp, hazard warning flashers, information display, radio

13-10A Electrically adjustable exterior mirrors

14-20A Power steering, cigarette lighter, heated front seats, electrically operated rear window blind, air circulation system, electric air conditioning, anti-theft alarm system, heated rear seats

15-15A Reverse lamps, cigarette lighter, glove compartment lamp, automatic transmission, automatic level control system, cruise control, ventilation for rear door windows, seat and mirror adjustment, radio

16-20A Fog lamps

17-20A Horn (not the pot noodle variety)

18-20A Fuel pump (useful to remove then run engine to de-pressurise fuel system when changing fuel filter etc!)

19-10A ABS, TC

20-20A Heated rear seats, electrically operated rear window blind, central locking, courtesey lamp

21-10A Main beam (left)

22-10A Dipped beam (left) headlamp range adjustment

23-10A Parking and tail lamps

24-

25-20A Sunroof

26-10A Number plate lamp, information display, headlamp washer system

27-20A Automatic level control system

28-10A Fog tail lamp

29-20A Terminal 30. constant current for caravan/trailer (pikey optional fit, can be used for simple audio instals)

30-10A Parking and tail lamps (right)

31-10A Dipped beam (right), headlamp range adjustment

32-10A Main beam (right), control indicators

33-30A Heater fan, air-conditioning system, electric air-conditioning system (climate)

34-40A Heated rear window

98-2003 cars1--30A Window operation

2--15A Brake lamps, hazard warning flashers

3--30A Windscreen wipers, windscreen washer system

4--15A Cooling fan

5--30A Electrically adjustable front seats

6--20A Radio

7--30A Electrically operated windows

8--10A Daylight running lamps (Scandinavia)

9--10A Automatic transmission (for the infirm)

10-30A Heated diesel fuel filter

11-10A Heated exterior mirrors

12-20A Courtesy light, tunk lamp, hazard warning flashers, information display, radio, navigation system

13-10A Electrically adjustable exterior mirrors

14-30A Power steering, cigarette lighter, heated front seats, electrically operated rear window blind, air circulation system, electric air conditioning, heated rear window

15-20A Reverse lamps, glove compartment lamp, automatic level control system, cruise control, seat and mirror adjustment, radio, heated rear seats, sun roof, instrument illumination, window operation, cooling fan, headlamp range adjustment

16-20A Fog lamps

17-20A Horn (not the pot noodle variety)

18-20A Fuel pump (useful to remove then run engine to de-pressurise fuel system when changing fuel filter etc!)

19-10A ABS, TC

20-20A Courtesy lamp, seat heating, central locking, rear window blind

21-10A Main beam (left)

22-10A Dipped beam (left) headlamp range adjustment

23-10A Parking and tail lamps

24-20A Coolant heating

25-20A Sunroof

26-10A Number plate lamp, information display, headlamp washer system

27-20A Automatic level control system, rear accessory socket

28-20A Fog tail lamp

29-30A Terminal 30. constant current for caravan/trailer (pikey optional fit, can be used for simple audio instals)

30-10A Parking and tail lamps (right)

31-15A Dipped beam (right), headlamp range adjustment

32-10A Main beam (right), control indicators

33-30A Heater fan, air-conditioning system, electric air-conditioning system (climate)

34-40A Heated rear window