Tried to post this yesterday but my freaking internet went down

Right then chaps.... here goes....

Let's cover the first look at diesel knowledge.... what i dont understand in

red

Induction:

ONLY AIR is drawn in to the cylinder. The downward motion of the piston lowers cylinder pressure and creates a vacuum for the air to enter.

Compression:

The piston then moves up and compresses the air raising cylinder pressure due to the air heating up during compression. Towards the end of this stroke the diesel is injected.

Power:

After the ''Delay period'' (the time span from injection to ignition) the piston is forced down as in the normal 4 stroke cycle. It's important to note that there is flame spread when the diesel ignites. this creates shockwaves and due to the high compression ratio the shockwaves hit the piston crown and the combustion chamber. this is called ''Diesel knock'' and is the tell tale sound of a diesel

There are 3 things that can be done to reduce the delay period, give quiter operation, better fuel economy and a smoother running engine:

1. increase temperature (higher compression ratio, the addition of glow plugs)

2. increased atomisation (breaking down the fuel.... increase injection pressure)

3. increased swirl (valve with a mask on the head, special piston crown shape)

next:

Direct Injection:

where the injector nozzle is directly in the combustion chamber and fuel injected straight in at the right time. simples

Indirect Injection:

where the injection of fuel is pre-swirled in to a ''pre-combustion chamber''.

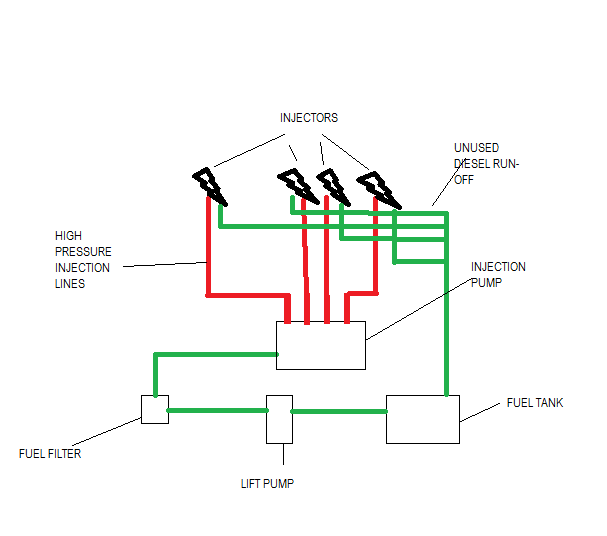

What i dont get is this... if the fuel and air are already mixed is it this thats pulled in on the induction stroke? or is just air pulled in and compressed and then this pre-mixed fuel/air mixture injected?A very, very, very awful picture i've drawn (sorry its a ''paint'' jobbie) of the main components in the diesel engine...

fuel is stored in the fuel tank and moved through the fuel lines by the lift pump. it then goes through a fuel filter

(this has a water bleed and air bleed... why would water or airget in your fuel lines???

the fuel then travels to the injector pump and from the injector pump to the injectors.

NOTE the red and green lines..... red are high pressure lines from the injection pump to the injectors which is about 2000psi. the green lines are low pressure lines just to move the fuel between tank and injector pump and also the excess not used from the injectors in to the ''run off''.

Author

Topic: Mechanic School Blog (Read 95983 times)

Author

Topic: Mechanic School Blog (Read 95983 times)