1

Maintenance Guides / Re: How To Clean Your 2.0L IACV and Breather Jet

« on: 02 November 2007, 12:52:22 »

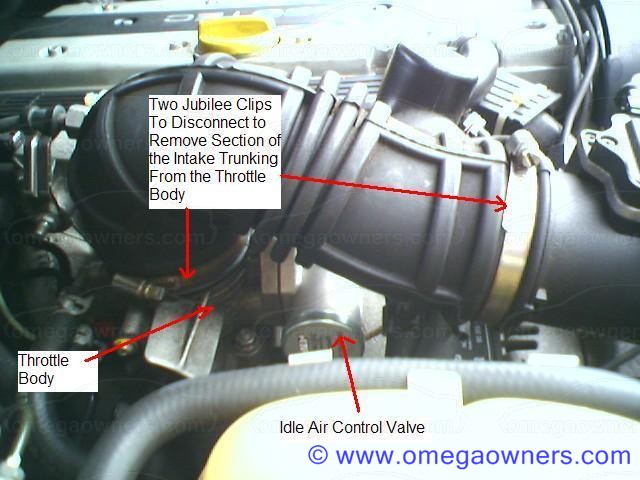

Now we come to the IACV.

Have a look at the following pictures. The exploded view was kindly

provided by 'Abiton', who took one apart to see what made it tick.

The Inlet hole to the IACV is deeper than the Outlet. This is because

it provides air to the hidden air passage ways that pass to the end

of the IACV and to the second of the Twin Valves.

Look at the exploded view and you will see the 2 kidney shaped slots

that pass through the valve to pass the air to the second valve.

It's these airways and the second valve that get coated and blocked

with oil.

Undo the 2 screws that secure the electric motor to the valve,

and slide the motor off the valve stem.

Fill the valve with carb cleaner or fuel. Ensure that you pour

or spray it down the inlet hole, so that it passes through the

hidden airways and down to the second valve down by the

flat end of the valve. Allow it to soak and agitate it by covering

all 3 holes (gloved fingers and thumbs works for me).

Stand it on its flat end with the inlet and outlet holes facing you.

Tilt it slowly away from you so that the cleaner and muck flows

away from the second valve, washes out the hidden airways, and

out via the end where you've removed the Electric Motor from.

This will ensure that you don't wash all the crap down to, and

block, the second valve orifice.

Repeat until clean and then thoroughly dry.

Put a little electric lube or vaseline on the shiny bit of the valve stem

that protrudes into the motor. Do not lube any other part of the valve!!

The only contact point on the valve is the stem that protrudes into the

motor. Any lubing anywhere else is not only pointless, but will dry onto

the valve body and act like sticky flypaper that will attract crud like ****

to a blanket.

Reassemble the valve. Spin the valve stem until you can see a small hole

in the valve plastic coating in the hole nearest the flat end of the valve.

Put a thin 'Podger' in the hole and draw the valve back towards the flat end

against the spring pressure.

When you release the 'Podger' from the small hole in the valve stem check

that the spring pressure returns the valve fully back towards the motor end.

Check this by trying to move the valve towards the motor end. There shouldn't

be any movement.

If it doesn't return, repeat by cleaning and lubing the valve stem inside

the motor bit until it does.

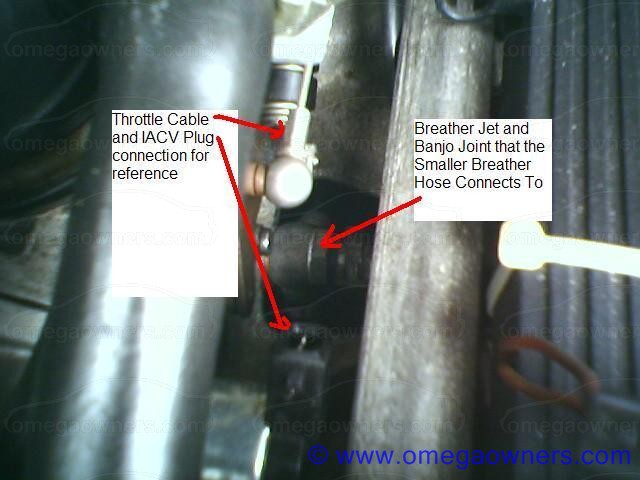

If you wish, clean your throttle body. That has already been detailed

by other good folk on this forum.

You may also wish to remove and clean the other breather hose, on the

back passenger side of the engine, that connects between your crankcase

and cam cover. This has also been covered on this forum. Some also

fit a flame trap mod to this hose.

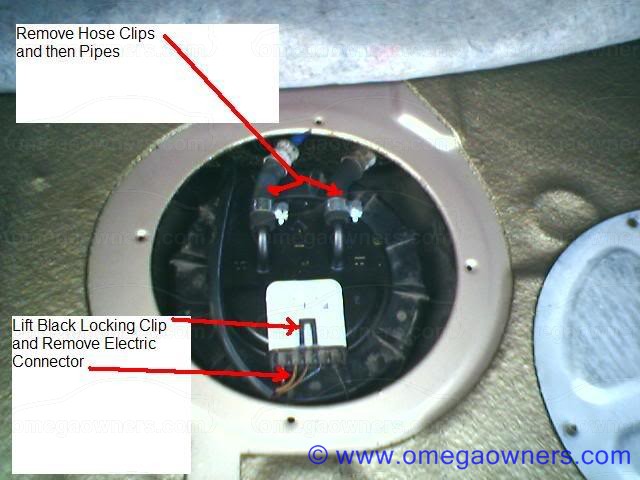

When you refit everything, ensure that you use a new gasket between

the IACV and the throttle body. If this gasket leaks internally, or draws

in air externally, your ECU will not be able to control your IACV.

This will give all sorts of defects from, high, low, or fluctuating RPM.

Now enjoy your smooth idling, non stalling, Omega limo!

Hope this helps, but remember that this is just one reason

that can cause your Omega to stall. A failing Crank Sensor, for instance,

can give similar cutting out symptoms.

Have a look at the following pictures. The exploded view was kindly

provided by 'Abiton', who took one apart to see what made it tick.

The Inlet hole to the IACV is deeper than the Outlet. This is because

it provides air to the hidden air passage ways that pass to the end

of the IACV and to the second of the Twin Valves.

Look at the exploded view and you will see the 2 kidney shaped slots

that pass through the valve to pass the air to the second valve.

It's these airways and the second valve that get coated and blocked

with oil.

Undo the 2 screws that secure the electric motor to the valve,

and slide the motor off the valve stem.

Fill the valve with carb cleaner or fuel. Ensure that you pour

or spray it down the inlet hole, so that it passes through the

hidden airways and down to the second valve down by the

flat end of the valve. Allow it to soak and agitate it by covering

all 3 holes (gloved fingers and thumbs works for me).

Stand it on its flat end with the inlet and outlet holes facing you.

Tilt it slowly away from you so that the cleaner and muck flows

away from the second valve, washes out the hidden airways, and

out via the end where you've removed the Electric Motor from.

This will ensure that you don't wash all the crap down to, and

block, the second valve orifice.

Repeat until clean and then thoroughly dry.

Put a little electric lube or vaseline on the shiny bit of the valve stem

that protrudes into the motor. Do not lube any other part of the valve!!

The only contact point on the valve is the stem that protrudes into the

motor. Any lubing anywhere else is not only pointless, but will dry onto

the valve body and act like sticky flypaper that will attract crud like ****

to a blanket.

Reassemble the valve. Spin the valve stem until you can see a small hole

in the valve plastic coating in the hole nearest the flat end of the valve.

Put a thin 'Podger' in the hole and draw the valve back towards the flat end

against the spring pressure.

When you release the 'Podger' from the small hole in the valve stem check

that the spring pressure returns the valve fully back towards the motor end.

Check this by trying to move the valve towards the motor end. There shouldn't

be any movement.

If it doesn't return, repeat by cleaning and lubing the valve stem inside

the motor bit until it does.

If you wish, clean your throttle body. That has already been detailed

by other good folk on this forum.

You may also wish to remove and clean the other breather hose, on the

back passenger side of the engine, that connects between your crankcase

and cam cover. This has also been covered on this forum. Some also

fit a flame trap mod to this hose.

When you refit everything, ensure that you use a new gasket between

the IACV and the throttle body. If this gasket leaks internally, or draws

in air externally, your ECU will not be able to control your IACV.

This will give all sorts of defects from, high, low, or fluctuating RPM.

Now enjoy your smooth idling, non stalling, Omega limo!

Hope this helps, but remember that this is just one reason

that can cause your Omega to stall. A failing Crank Sensor, for instance,

can give similar cutting out symptoms.