Well,

My Omega, I have now pretty much finished it. It is in a condition that you can drive it in, comfortable. Bit of background.

The car belonged to a friend of mine, who received a rather large list of failures in the space of a very short time. I replaced the waterpump, cambelt and tensioners for him and he had the car MOT'd. He drove it for a short while, but found the manifold was no longer at its best, and the rear diff was knackered. He lost all interest in the car and just gave it to me, as he didn't want to scrap it and would rather see something useful become of it.

I was in the position of wanting another Omega, but not wanting to shell out a huge amount of cash, so I took the project on. First thing was to draw up a list of repairs needed.

- replacement rear diff

- manifold

- associated gaskets

- lambda probe, to correct an ECU code I pulled off

I learnt quite a few lessons from this project, which I will pass on in this story.

I scoured Ebay and found a seller breaking a 2.0 Auto Omega. I purchased the

- Rear Diff (£40 inc P&P)

- Manifold (£10 inc P&P)

The manifold had some snapped studs, so I attempted to drill them out, two hours of drilling, I had the holes cleared and threads re-tapped. I removed the old manifold, and found it very clearly cracked at the point where it goes from 4 to 2 and joins the downpipe.

So, I put the new one on (or rather my second hand replacement) and fitted the new gaskets.

- Manifold gasket (£5.95 +VAT)

- Downpipe Gasket (£1.59 +VAT)

Got it all screwed back together, but found the new manifold was slightly cracked, and I could not get a good seal from my downpipe join. At this point I planned to purchase a new manifold, so turned my attention to the rear diff.

So began a 4 day marathon.

1 - Get the car up on axle stands, at the rear.

2 - Undo the driveshafts, 6 bolts, plenty of plus gas (ideally) of WD40, a breaker bar is essential here.

3 - Remove both driveshafts (crowbar essential here)

4 - Diff oil will spill out at this point, have a tray ready.

5 - Get a jack up and under the diff, the rear of the diff is the heaviest. I placed two jacks and a slab of wood between them to make a platform to support the diff. I then started to undo the various bolts.

6 - With all the bolts undone and remove, and ABS sensors disconnected, I started to slowly lower the diff, easing each jack down at a time.

7 - I was confronted with the following scene.

The diff was out, I had a complication with one of the driveshafts, so this had to stay in, making removal a tiny bit difficult.

8 - I was left with this void, waiting to be filled with heavy differential!

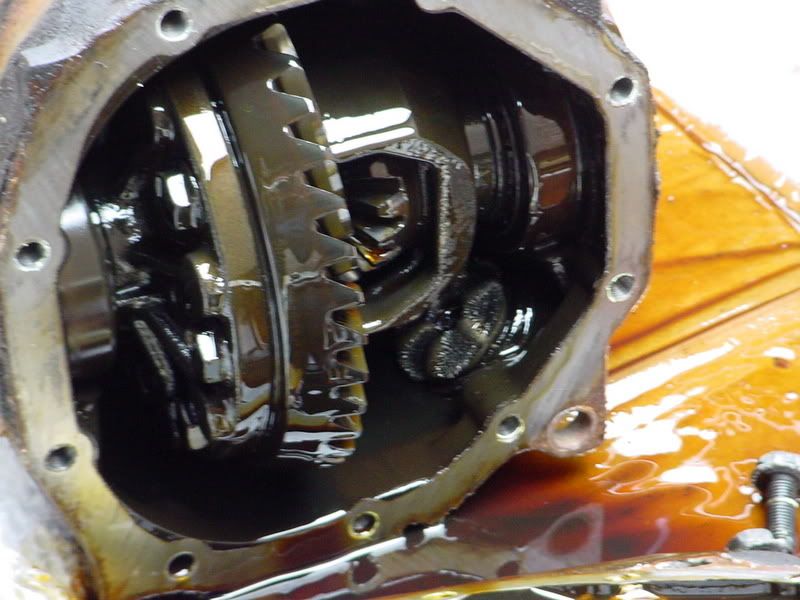

9 - I dismantled the old diff to get the driveshaft out, this involved removing the back and levering the diff out.

As you can see, the magnets have trapped a lot of swarf. I traced the diffs failure to a collapsed pinion bearing.

10 - I lifted the new diff onto my homemade platform and carefully wheeled iit under the car. It rolled off once (not a huge drop!!) but this was annoying, as I had to inch it under the car, as the platform was a little precarious.

11 - I raised the diff up slowly and got the two rear bolts in. I let the front of the diff down on the jack, which allowed me to mate the prop up, this slipped in and popped into place as I raised the diff to get the three remaining bolts in.

12 - I tightened to manufacturers specs, and was left seeing this, a satisfying moment, where I left the project for lunch.

13 - Both driveshafts back in, tightening each sides six bolts to manufacturers torque, which, according to my Torque wrench equated to bl**dy tight!.

14 - Started the car, with both wheels now on, but off the ground, and ran in first, second and third. No noises.

15 - Big test, lowered the car and ran up and down the drive, no noise!!!!.

Total cost of the diff job??

£40 for the diff

£6 for some EP90

£46 + 4 days of my time. A massive learning curve that was well worth the massive bruise I got on my elbow, and the large quantities of EP90 I got in my hair!.

Onto the manifold.

I sold the Saab and with the £600, I set aside some money for the Omega. I rang Autovaux and ordered...

- Manifold £71.55 +VAT (much cheaper than I thought)

- Gaskets (same as above)

- Lambda probe £69.95 +VAT

Fitted all of this last saturday. I removed the whole exhaust system and split the front pipes from the rest of the system for re-assembly. Everything went back on well, and so far, appears leak free.

The big moment had approached, the test drive. I eased the car out of the drive and off down the road. Performance was instantly better than the drive home all those weeks before. The rear of the car was silent. Pickup was acceptable too, but the frontpipes are a little rattly, but this is due to them being a cheap, pattern part.

So, for around a total outlay of £300, I saved a car that I had been given free of charge. Only a 2.0 I know, but, an interesting project and quite an eye opener.

Lessons learned.

- Don't bother with second hand Ecotec Manifolds, new ones are cheap enough from Autovaux.

- Invest in a good 3 tonne jack, my 2 tonne small affair struggled with the shuffling around.

So, there we go!!!

James

Author

Topic: My Omega - A quick rundown of the project!! (Read 3384 times)

Author

Topic: My Omega - A quick rundown of the project!! (Read 3384 times)